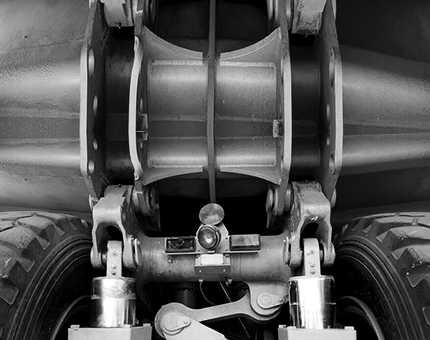

A large open pit coal mine began to experience frequent damage to truck frames. This damage lead to failures which in turn created significant amounts of downtime and expensive repairs. This also resulted in severely erroneous payload measurements by the trucks on-board weighing systems which rely on suspension strut pressure data, amount other metrics.

MaxMine Application

Following the implementation of MaxMine, it was determined that overcharged suspension cylinders were a root cause of these failures, specifically the incorrect recharging procedures. A dedicated crew of artisans and technical specialists recharged and reset ride heights along with re-calibrating payload measurements of all the machines in the fleet. MaxMine established mechanisms to remotely measure strut pressures before and after recharging and having analysed the data the correct procedure for recharging was formulated.

Results

12%

increase in machine availability

91%

reduction in suspension related alerts generated daily